Open Cast Polyurethane Moulding

We cast polyurethane MDI and TDI elastomers in a variety of shapes, hardness’ and colours. Large parts can be poured in the over 19 m³ of oven space we have on site.

The largest ovens can handle parts within:

- 4m long x 1.2m wide x 600mm high

- 3m long x 1.2m wide x 1.2m high

- 1.7m long x 1.7m wide x 1.45m high

Engineering and Machining

Capabilities:

- CnC Lathe – 460mm ø x 2.5m long

- CnC Mill – Travel 1.7m (x) 460mm (y) 615 (z)

- Largest Lathe – 640mm ø x 5m long

This flexibility allows us to manufacture most moulds, and machined parts in house, significantly reducing costs and lead times.

Abrasive Blasting and Corrosion Removal

With internal dimensions of 2.2m wide x 3m deep x 2.4m high our sandblasting booth can accommodate large parts for surface preparation and cleaning.

We use Metablast 12 grit, a metal blasting media for an aggressive clean of corroded or coated parts. After years of testing we find this gives the best resultant surface for bonding polyurethane to both ferrous and non-ferrous metals.

Having our own on site blasting means freshly prepared parts can be bonded within minutes, removing the chance of surface degradation or corrosion and ensuring the strongest bond.

CAD Part and Mould Design

Using Solidworks® Professional CAD software we have in house design and drafting capabilities that include part and mould design. 3D modelling of parts and assemblies and direct CAM output to our machine shop.

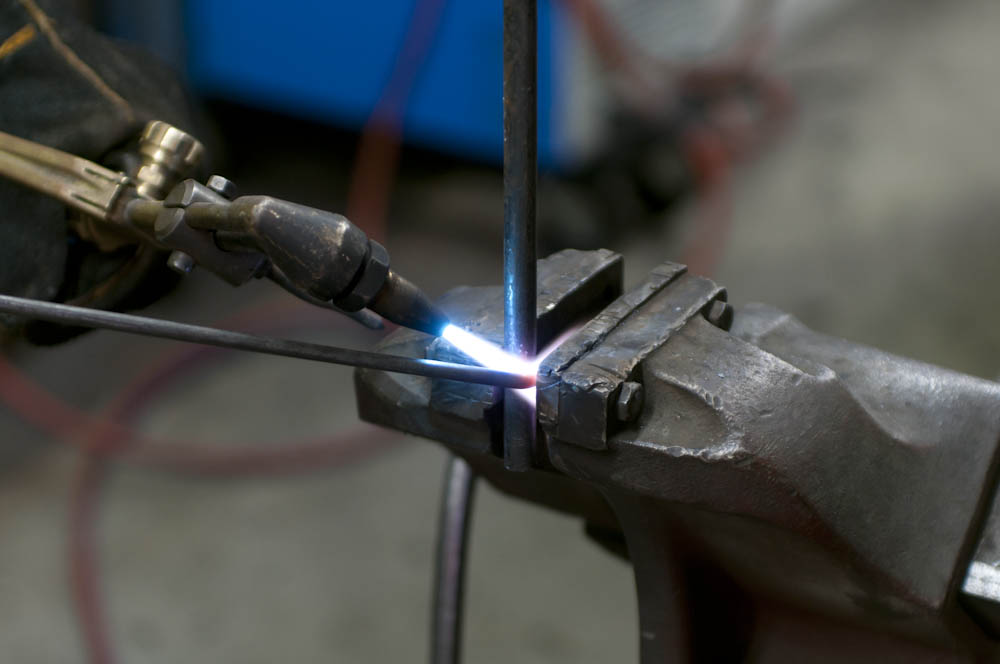

Fabrication and Welding

Fabrication Capabilities:

- water and laser cutting

- sheet folding and rolling

- brake presses and guillotines

- MIG welding

With these abilities we can make moulds and fabricated parts (i.e. plenum chambers) in house.